Layering Transitions and Dynamics in Confined Liquid Films

Rashmi Patil and Jordan Vincent

Results and Discussion

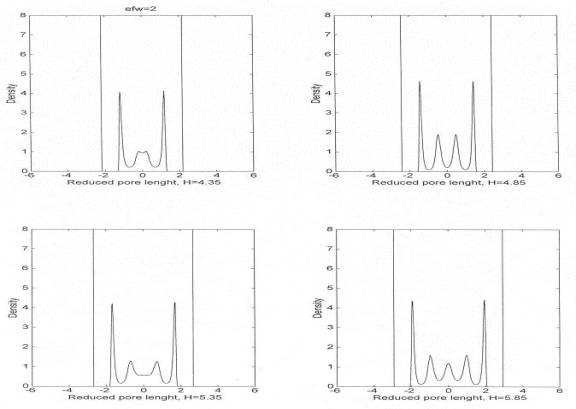

The

density profiles r(z)

for the confined film, recorded versus distance in the direction normal to the

surfaces, for a sequence of separations (gaps) D between the confining surfaces

is shown in Fig. 1. Here

the reduced bulk density r*

of the LJ fluid is 0.65 and efw=2eff. These profiles

show clear oscillatory patterns. For wide gaps a uniform bulk density

distribution develops in the middle of the confined film, with layering near

the two surfaces.

Fig. 1 Equilibrium density profiles for the

commensurate film along the z direction (normal to the confining solid

surfaces). The gap widths (H) for which the profiles were calculated are

indicated. Note that the liquid density outside the confinement is uniform and

remains constant for all values of H.

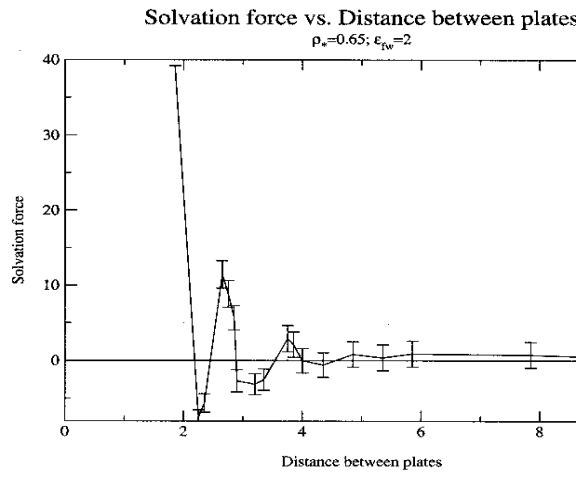

Solvation

forces f (H) recorded during the approach of the two surfaces are shown in Fig.

2. It is the total force exerted by the confined liquid on the confining

surfaces and this is the same as the force, which would be required in order to

hold the two surfaces at the corresponding separation. The layering transitions

in the confined films are portrayed in the solvation force oscillations (Fig. 2),

with local positive force maxima corresponding to configurations with well-formed

layers.

Fig. 2 Equilibrium solvation forces f in nN plotted

versus the width of the confining gap in A for r*=0.65 and r*=0.78. Dashed line: efw= eff; Solid line: efw=2eff; Dotted and dashed line: efw=4eff.

Fig. 3 shows a plot of solvation force vs. the distance between the plates with error bars. Though error bars were calculated for all cases they are not plotted to facilitate easy observation of trends. Irrespective of the distance between the plates, the error bars were nearly constant at about 1.4kT/e. It is suspected that it is largely due to systematic error but needs to be confirmed by running the code for longer times.

Fig. 3 Equilibrium solvation

forces f with error bars in units of kT/e plotted versus the width of

the confining gap in units of sigma for r*=0.65 and efw =eff.

Further

insight into the layering transition processes is obtained from Fig. 4 which records of the

number of atoms in the confined region N vs. the distance between the confining

surfaces (H). N varies in a step-like manner, with sharp drops in the number of

confined atoms occurring for the transition from n-layer film to an (n-1)-layer

one, with the steps becoming sharper as n decreases. This is because narrowing

the gap width results in expulsion of atoms from the confined region (squeezing

out of the film) and transition to a film with a smaller number of layers.

Fig. 4 Number of molecules in the confining gap n

plotted versus the reduced pore length for r*=0.65 and r*=0.78.

Plots of N/H versus H (see Fig. 5 where N/H is proportional to the number density of molecules in the gap) suggest that below a certain thickness (~6 layers) the films exhibit certain features characteristic of the solid-like response; that is, when the confining gap is slightly reduced, starting from one of the well formed layered configurations of the film with nL layers (corresponding to the maxima in the solvation force shown in Fig. 2), the film yields through the expulsion of approximately a layers worth of molecules into the surrounding liquid, causing a sharp decrease in the confined film density. During further reduction of the gap width, the number of confined molecules remains almost constant (plateaus of N, Fig. 4), with an associated increase of the confined film density (Fig. 5), which is accompanied by enhancement of the order in the film. This process continues till a gap corresponding to a maximally ordered layered film (with nL 1 layers) is reached, for which the confined film density maximizes. This sequence of events is repeated with a period of ~0.35 nm.

Fig. 5 Number of molecules in the confining gap Nper

unit gap width H plotted versus the gap width H in A for r*=0.65. The meaning of the lines remains the

same as in fig. 2.

Fig. 6 shows ln(z1,max/z 1,min), ln(z2,max/z

2,min) and ln(z3,max/z3,min)as a function of

pore length for r*=0.65.

The various z's have been defined in Fig. 1. ln(z1,max/z 1,min)

gives a measure of the barrier a particle has to overcome in order from one

layer to the adjacent one. These profiles show clear oscillatory patterns. The

local maxima correspond to configurations with well-formed layers.

Fig. 6 Plot of ln(z 1,max/z 1,min), ln(z 2,max/z 2,min)

and ln(z 3,max/z 3,min)

as a function of pore length for r*=0.65. The meaning of the

lines remains the same as in fig. 2.

Fig. 7 shows the plot of the pair-distribution (PDF).

Concentrating on the first two peaks of the PDF, we note that two smooth peaks

exist at high pore widths. As the degree of confinement is increased, the first

peak becomes more pronounced in magnitude and narrower in width and the first

minimum decreases in magnitude.

Fig. 7 plot of the pair-distribution

(PDF) for reduced pore lengths 2.75s and 2.35s.

These

results suggest that the confined spherical LJ liquid exhibits certain features

of characteristic of solid-like response; that is, when the confining gap width

is slightly reduced, starting from one of the well-formed layered

configurations of the film with n layers, the film yields through expulsion of

approximately a layer worth of atoms into the surrounding liquid, causing a

sharp decrease in the confined film density. Further reduction of the gap

width, the number of confined atoms remains almost constant that is accompanied

by the enhancement of the order in the layered structure of the film. This

process continues until a gap width corresponding to a maximally ordered layered

film (with n 1 layers) is reached, for which the confined film density

maximizes.

The

density profiles r(z) for the confined film, recorded versus distance in the direction

normal to the surfaces, for a sequence of separations (gaps) D between the

confining surfaces is shown in Fig. 1. Here the reduced bulk density of the LJ

fluid is 0.65. These profiles show clear oscillatory patterns. For wide gaps a

uniform bulk density distribution develops in the middle of the confined film,

with layering near the two surfaces.