3D KMC

simulation on the precipitation in the annealed ternary alloy system

Xuan Zhang, Mengqi Huang

Abstract

Kinetic

- Introduction

Precipitate hardening is widely used to increase the yield strength of alloys. However, this strengthening mechanism depends on the size of the precipitates. The critical radius is typically 5~30 nm [1]. Those larger precipitates will bent the dislocations rather than cutting through them, which decreases the strength of the material [2]. Considered the fact that precipitates will grow during heat treatment, normal alloys will lose their strength at high temperature. Therefore, reducing the size of the precipitates, especially at high temperature, is desired to improve the mechanical property of the alloys.

Cu-Nb alloy (10 at.% Nb) were found to lose the strength because of the

formation of large precipitates (40~80 nm) at

The XRD results in Fig. 1are kind of interesting, and it is possible to

get some important information about how the kinetics is when this material is

subjected to thermo annealing. Samples were treated in three different

conditions: (1) direct annealing at 600![]() for 2 hours; (2) first annealing at 600

for 2 hours; (2) first annealing at 600![]() for 2hrs, then annealing at 700

for 2hrs, then annealing at 700![]() for 2 hours; (3) direct annealing at 700

for 2 hours; (3) direct annealing at 700![]() for 2 hours. Under condition (1), two peaks besides the Cu

peak are observed: one at pure Nb position, and the other is in between the

peak position of Nb and W, which suggests Nb-W alloy particles are formed, and

the average particle size and concentration can be get from the half-maximum

width and position of the peak, respectively. Under condition (2), two things

happened compared with condition (1), which are, first, the alloy particle peak

shift significantly to W peak side, and second, pure Nb peak grew. Under

condition (3), only the alloy particle peak is observed besides the Cu peak.

for 2 hours. Under condition (1), two peaks besides the Cu

peak are observed: one at pure Nb position, and the other is in between the

peak position of Nb and W, which suggests Nb-W alloy particles are formed, and

the average particle size and concentration can be get from the half-maximum

width and position of the peak, respectively. Under condition (2), two things

happened compared with condition (1), which are, first, the alloy particle peak

shift significantly to W peak side, and second, pure Nb peak grew. Under

condition (3), only the alloy particle peak is observed besides the Cu peak.

Since the two facts that (1) W is miscible with Nb [4],

but has a positive heat of mixing with Cu [5],

and (2) W start to be mobile above

In order to prove our assumption, we use KMC simulation to study the dynamic evolution of the precipitates in a simplified ternary alloy system. First we will find out the proper parameters so that our simplified KMC code can qualitatively present real materials; then we will compare our 2-step annealing simulation results with the XRD spectrums.

Fig. 1.

XRD results for different annealing conditions.

- KMC approach

2.1 KMC introduction

Kinetic Monte Carlo (KMC) is widely used to study diffusion-controlled phenomena, and its main advantage is that it has a good compromise between the atomic scale mechanism and the macroscopic time scale. Given a system with initial configuration, and a set of transition rate between different configurations, the evolution of the system can be studied [6].

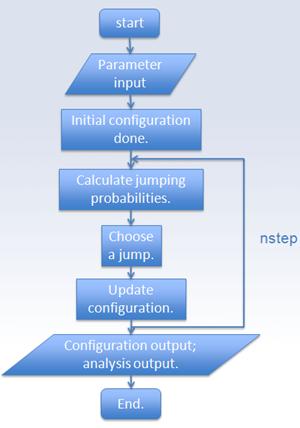

2.2 Flowchart

2.3

KMC model

The goal of this project is to build a

system that can best describe the Cu-Nb-W ternary alloy system. The simulation

box is set to have 64*64*64=262144 atoms in total, with a fcc crystal structure.

There is one and only one vacancy in the box. In the binary system, we choose

90 at% type A atoms and 10 at% type B atoms, and in the ternary system, we replace

1 at% of A to C atoms, thus having a ![]() system. Only first

nearest neighbor interaction is considered. The exchanging rate between vacancy

and its neighbors is determined by the local environment and the saddle point

energy of that atom, i.e. when exchanging happens, the atom and vacancy need

first to break all the bonds they have with the local environment and then the

atom jumps to the saddle point position, then to the former vacancy position.

system. Only first

nearest neighbor interaction is considered. The exchanging rate between vacancy

and its neighbors is determined by the local environment and the saddle point

energy of that atom, i.e. when exchanging happens, the atom and vacancy need

first to break all the bonds they have with the local environment and then the

atom jumps to the saddle point position, then to the former vacancy position.

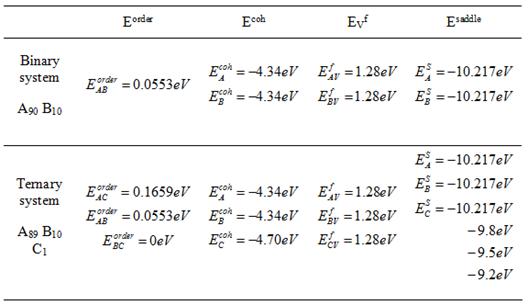

The energies envolved are energies of the

bonds (![]() ) and the saddle point energies

) and the saddle point energies![]() (it is assumed the same type of atoms have the same saddle

point energy). The saddle point energies are set to be input, based on

the value for pure A system with just one vacancy (-10.217eV). The rest of the

energies are calculated in the code, based on the cohesive energy of pure A, B,

C systems (

(it is assumed the same type of atoms have the same saddle

point energy). The saddle point energies are set to be input, based on

the value for pure A system with just one vacancy (-10.217eV). The rest of the

energies are calculated in the code, based on the cohesive energy of pure A, B,

C systems (![]() ), the ordering energy between AB, AC and BC (

), the ordering energy between AB, AC and BC (![]() ), and vacancy formation energy in pure A, B, C (

), and vacancy formation energy in pure A, B, C (![]() ). They are set to be input and their values are chosen to

be:

). They are set to be input and their values are chosen to

be: ![]() (experimental data for

pure Ni),

(experimental data for

pure Ni), ![]() (considering the fact

that C represents tungsten, whose bonds are stronger than A and B),

(considering the fact

that C represents tungsten, whose bonds are stronger than A and B), ![]() [7]

(typical experimental data for Cu-Co system),

[7]

(typical experimental data for Cu-Co system), ![]() ,

, ![]() (considering the fact

that Cu and Nb only have a slightly positive heat of mixing but Cu and W have

very large positive heat of mixing, and that of Nb and W is generally

negligible since Nb and W are miscible.),

(considering the fact

that Cu and Nb only have a slightly positive heat of mixing but Cu and W have

very large positive heat of mixing, and that of Nb and W is generally

negligible since Nb and W are miscible.), ![]() (experimental data for

pure Cu [8],

but this value has finally been adapted for the reason related to the time

scale, see section 3.1.). All parameter needed in our code are listed in

Table.1.

(experimental data for

pure Cu [8],

but this value has finally been adapted for the reason related to the time

scale, see section 3.1.). All parameter needed in our code are listed in

Table.1.

Table. 1. All the energy parameters for

KMC model.

- Results and discussion

3.1 Real time scale: determination of EVf

The vacancy formation energy determines the

relationship between KMC simulation step and real time. For real material, the

vacancy concentration at thermal equilibrium is about 10-10~10-14.

In our model, we increase it to ![]() . Accordingly, more atom-vacancy exchanges occur in the model,

which means our KMC simulation is much faster than real time experiments. The

ratio between real time and KMC time is a function as temperature:

. Accordingly, more atom-vacancy exchanges occur in the model,

which means our KMC simulation is much faster than real time experiments. The

ratio between real time and KMC time is a function as temperature:

![]()

Where XVeq is the vacancy concentration at thermal equilibrium:

![]()

Table 2 lists several A values at different temperatures, if we assume all

the vacancy formation energy are the same, e.g. ![]() (The reason for this assumption will be discussed below). Based

on these parameters, four annealing simulations were run for 4*1010

KMC steps in a temperature range from 100℃

to 500℃. By scaling to the real

time scale, the changes of the average particle sizes with time for both binary

and ternary systems are plotted in Fig. 2. It is shown that the ternary system

has much smaller precipitates (~103 atoms) than the binary system

(~104 atoms). The relation between adding tungsten and the decrease

of particle size will be discussed more later.

(The reason for this assumption will be discussed below). Based

on these parameters, four annealing simulations were run for 4*1010

KMC steps in a temperature range from 100℃

to 500℃. By scaling to the real

time scale, the changes of the average particle sizes with time for both binary

and ternary systems are plotted in Fig. 2. It is shown that the ternary system

has much smaller precipitates (~103 atoms) than the binary system

(~104 atoms). The relation between adding tungsten and the decrease

of particle size will be discussed more later.

Fig. 2 also illustrated a fact that the lower the annealing temperature,

the more time it will take to form comparable size particles as higher

temperature. If we choose a slightly different vacancy formation energy (e.g.

1.6eV), the new A values will yield much longer nucleation time: for 500℃ t~30h,

and t~2700h for 400℃. Compared

with real annealing experiments, ![]() is a more reasonable choice

for our model.

is a more reasonable choice

for our model.

|

T(℃) |

100 |

300 |

400 |

500 |

|

A |

6.9E11 |

6.7E5 |

1.5E4 |

821 |

Table 2. Values

of the ratio A at different temperatures.

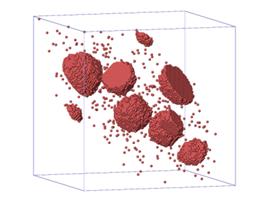

(b) (a) Ternary A89 B Binary A90 B10

(d) (c) T=300℃

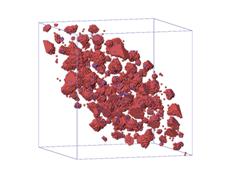

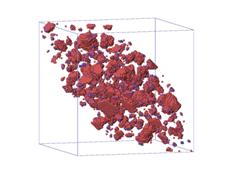

Fig. 2. (a) and (b) show average particle

size as a function of real time at different temperatures: (a) is for binary

system, (b) is for ternary system. (c) and (d) are visualization pictures of

the alloy structures for both systems at T=300℃. The red dots

are Nb atoms, the blue ones are W atoms. Both (c) and (d) are plotted from the

final time step (~108 s), when <n> changes with time very

slowly.

3.2 Precipitate size vs. time

As shown in Fig. 2, the average precipitate size of the ternary alloy is much smaller than that of binary alloy, approximately one order of magnitude lower when the rest of the parameters are set to be the same. It is also found that the two systems follow different growth law—the slop of Fig. 2(a) is higher than that of Fig. 2(b). This phenomenon agrees quite well with what we found in experiment, i.e. the third element behaves like a controller to the precipitate growth.

3.3 ![]()

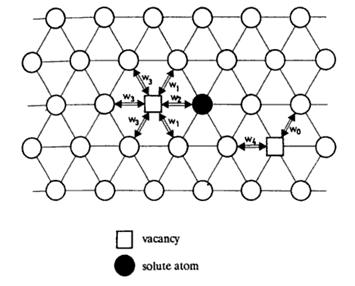

To provide a quantitative description of the mobility of atoms, the five-frequency model 9 is adopted. The schematic diagram of Figure.3 shows the five different frequencies for vacancy jump in an infinite dilute solution if only first n. n. is considered. To be simple, w0 is the unperturbed host atom-vacancy exchange frequency, w1 is the frequency that vacancy jumping around the solute atom, w2 is the solute atom-vacancy exchange frequency, w3 is the dissociation frequency of the solute atom and the vacancy, and w4 is the association frequency of the solute atom and the vacancy. By calculating the relative energy for each type of jump, those five frequencies are determined by the following equation:

![]()

Where ![]() is the base frequency

which is set to be

is the base frequency

which is set to be ![]() by input, and

by input, and ![]() . Figure shows the relation between w2 and

. Figure shows the relation between w2 and ![]() at 300

at 300![]() , assuming only one C atom in a pure A matrix. Since w2 is

the direct C-V exchange frequency, the lower the value, the less the mobility

of C.

, assuming only one C atom in a pure A matrix. Since w2 is

the direct C-V exchange frequency, the lower the value, the less the mobility

of C.

Figure. 3. Five-frequency model for

vacancy jumps in the presence of a foreign atom, showing (111) plane. [9]

Figure. 4. The frequency of the exchange between the

solute atom and the vacancy as a function of the saddle point energy of atom C.

From Figure.4 we can see that when ![]() , w2 is so low that C atoms are indeed immobile at 300

, w2 is so low that C atoms are indeed immobile at 300![]() . This trend can also be seen from Figure.5, which is the

visualizations of microstructures at the same real time for the four different

. This trend can also be seen from Figure.5, which is the

visualizations of microstructures at the same real time for the four different ![]() .

.

(a)

(b)

(c) (d)

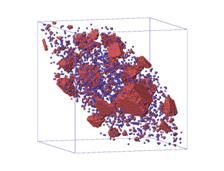

Figure.5. Visualization of

microstructure of precipitates at four different saddle point energy of atom C:

(a) ![]() ; (b)

; (b) ![]() ; (c)

; (c) ![]() ; (d)

; (d) ![]() .

.

In our

experiment, when we first annealed the sample at 600![]() , tungsten should be immobile

based on the experimental data from Cu-W binary system, and when we annealed

the sample at 700

, tungsten should be immobile

based on the experimental data from Cu-W binary system, and when we annealed

the sample at 700![]() , tungsten should starts to be mobile. Because our simulation

does not mean to reproduce everything in experiment, we just chose

, tungsten should starts to be mobile. Because our simulation

does not mean to reproduce everything in experiment, we just chose ![]() and chose

and chose ![]() to be the condition

similar to

to be the condition

similar to ![]() in experiment. Further

we found out that at

in experiment. Further

we found out that at ![]() in our simulation, C atoms starts to be mobile, which is

kind of the case that happened in experiment at 700

in our simulation, C atoms starts to be mobile, which is

kind of the case that happened in experiment at 700![]() . These are the simulation condition we use in the following

part.

. These are the simulation condition we use in the following

part.

3.4 Modeling of experiments

Based on the analysis above, we chose three conditions as a reflection

of experimental conditions: anneal at 300![]() , anneal at 300

, anneal at 300![]() then anneal at 500

then anneal at 500![]() , anneal at 500

, anneal at 500![]() . Any of the temperatures has been maintained for relatively

long enough time to have distinguishable configurations and reach a

quasi-steady state, since in the annealing situation, if waiting long enough,

the final equilibrium state is just one big BC particle in A matrix, and this

is obviously not what we want. Figure.6 shows the visualizations of

microstructures in the three conditions. Different atom distributions and particle

size distributions are observed.

. Any of the temperatures has been maintained for relatively

long enough time to have distinguishable configurations and reach a

quasi-steady state, since in the annealing situation, if waiting long enough,

the final equilibrium state is just one big BC particle in A matrix, and this

is obviously not what we want. Figure.6 shows the visualizations of

microstructures in the three conditions. Different atom distributions and particle

size distributions are observed.

(a)

(b)

(c)

Figure.6. Visualization of microstructures of precipitates under three

different conditoins: (a) directly annealing at 300![]() ; (b) first annealing at 300

; (b) first annealing at 300![]() , then annealing at 500

, then annealing at 500![]() ; (c) directly annealing at 500

; (c) directly annealing at 500![]() .

.

|

|

annealing temp (C) |

Amount of B in matrix |

Amount of C in matrix |

|

1 |

300 |

5% |

69% |

|

2 |

300+500 |

<13% |

<50% |

|

3 |

500 |

<11% |

<41% |

Table.3. Distribution

of B and C atoms under three different conditions.

|

Annealing

temp (C) |

ntot |

<natom> |

|

300 |

22 |

1170 |

|

300+500 |

34 |

726 |

|

500 |

82 |

298 |

Table.4. The

total number of precipitates and the average size (the average number of atoms

in particles) under three different conditions.

Table.3 shows the atom distribution in each condition, and Table.4 shows

the total number of particles and their average size (average number of atoms)

in each condition. These data show us a picture similar to what happened in

experiment. At 300![]() , 69% of C atoms are in the matrix, which is an indication of

the immobility of C, so the A and B atoms behave quite like in AB binary

system, which can be seen from the small value of ntot and large value of

<natom>. If further annealing at 500

, 69% of C atoms are in the matrix, which is an indication of

the immobility of C, so the A and B atoms behave quite like in AB binary

system, which can be seen from the small value of ntot and large value of

<natom>. If further annealing at 500![]() , there is a significant reduction (more than 19%) of number

of C atoms in the matrix, while a simultaneous increase of B atoms in the

matrix. Therefore, the ratio of number of B atoms in particles and number of C

atoms in particles decreases, i.e. more C in particles, which gives the shift

of the XRD alloy particle peak to tungsten side in experiment. And since there

are more B atoms in the matrix, the number of B atoms that can go to surface increases,

which gives the increase in intensity of Nb peak in XRD profile. If going

directly to 500

, there is a significant reduction (more than 19%) of number

of C atoms in the matrix, while a simultaneous increase of B atoms in the

matrix. Therefore, the ratio of number of B atoms in particles and number of C

atoms in particles decreases, i.e. more C in particles, which gives the shift

of the XRD alloy particle peak to tungsten side in experiment. And since there

are more B atoms in the matrix, the number of B atoms that can go to surface increases,

which gives the increase in intensity of Nb peak in XRD profile. If going

directly to 500![]() , since C atoms start to be mobile, they behave as strong

traps for B atoms, thus giving a sharp reduce in particle size, which is also

shown obviously in XRD profile, i.e. the half-maximum width of alloy particle

peak of annealing at 700

, since C atoms start to be mobile, they behave as strong

traps for B atoms, thus giving a sharp reduce in particle size, which is also

shown obviously in XRD profile, i.e. the half-maximum width of alloy particle

peak of annealing at 700![]() is much smaller than that of either annealing at 600

is much smaller than that of either annealing at 600![]() or annealing first at 600

or annealing first at 600![]() then 700

then 700![]() .

.

- Conclusions

Although our KMC model is quite simple, the results we have are qualitatively in good agreement with experimental observations, providing us with some insights of the atomic scale mechanism. The precipitation size in binary alloys AB will increase drastically without limitation. Just by adding 1 at% of a third element C, which is much less mobile at all temperatures compared with the other solute element B and has a very high heat of mixing with the matrix element A, the precipitation size has been reduced significantly and under control. The mobility of C is the key point to the precipitation process. In general the more immobile C is, the smaller the average size is. But if at a temperature when C is indeed immobile, the material will behave more like binary material, and large precipitates will be formed. The mobility of C is mostly determined by its saddle point energy. One particular saddle point energy is chosen to make C a representation of W in the Cu-Nb-W alloy, and the experiments were re-performed in simulation. Again the mobility of C showed its importance. To make our explanation more convincing, more details need to be considered, and more supportive data are required.

Reference